Rotomolding: Shaping the Future of Plastic Products

Plastics are all-pervasive, they can be present in almost every area of our way of life from playthings to wrapping, as well as vehicle pieces. It’s amazing how something so useful and popular in your day-to-day lives is created. Probably the most impressive ways to develop high quality plastic-type material merchandise is thru a procedure referred to as rotational molding, also called Rotomolding. It’s a modern approach that’s transformed plastic-type developing and manufacturing, rendering it inexpensive and successful. In today’s post, we are going to delve greater into Rotomolding, exploring what it is, the way it works, its advantages, and several of the products made from this method.

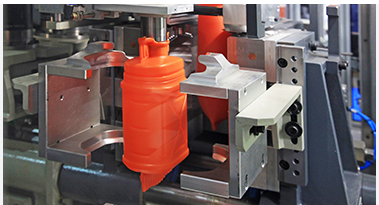

Rotomolding can be a process that involves melting plastic-type resin in the hollow mold, which happens to be then rotated on two perpendicular axes simultaneously. The centrifugal push produced distributes the dissolved plastic-type equally on the mold work surface, making a seamless and flaw-free of charge aspect. This process persists before the wanted density and form are achieved, at which point the mildew is cooled to firm up the plastic-type material materials. The shaped part is going to be taken out, and also the procedure commences once again.

An advantage of Rotomolding is when cost-effective it is actually, as it can develop elements in low quantities without having to put money into pricey and complex tooling needed in other molding methods. The molds necessary for this technique are less complicated and fewer costly to create, which means producing elements can be done with minimum expense. This method of manufacturing also provides for the production of sizeable components, without the need for expensive machinery which translates to an expense-efficient choice.

Rotomolding is yet another flexible process that will make products in custom shapes, sizes, and colours. A wide range of plastic materials may be used, which include go across-linked polyethylene, conjugated polypropylene, and linear very low-denseness polyethylene, for example. By using specific molds, complex models and designs can be accomplished without having to sacrifice the architectural integrity in the merchandise. These properties make Rotomolding ideal for goods which range from kayaks and playthings to bigger goods such as wastewater treatment techniques and chemical tanks.

An additional advantage of Rotomolding is the fact that items generated are solid, long lasting, and resistant to wear. The parts have the freedom from welds and seams, which makes them more durable and much less at risk of tension fractures and holes. The smooth nature from the pieces also makes certain they are watertight and proof against water leaks, which makes them ideal for utilize in harsh situations. This amount of longevity makes rotomolded elements well suited for items utilized in challenging environments such as gardening applications, canisters, and play ground equipment.

quick

Rotomolding continues to reinvent industrial production by giving an eco-warm and friendly, inexpensive, and flexible solution for the creation of plastic material merchandise. The seamless character, customizability, and durability of rotomolded elements make it possible for businesses and industries of any size to profit with this impressive procedure. From making merchandise easy and sizeable to parts that could stand up to the rigors of unpleasant environments, Rotomolding can be a procedure that businesses do not want to disregard. For that reason, this is basically the perfect response to developing higher-high quality plastic material elements and expediting creation.